Program Flow

In ICA 40, we fulfill the needs of factory transformation. Here are the five steps of how we engage with our customers to provide them with precisely the solution they need.

Step 1: Enquiry

We’re scheduling a brief online meeting to understand your company’s manufacturing setup and identify areas for improvement, particularly in manufacturing transformation. Through open dialogue, we’ll discuss your challenges and goals to offer initial insights and strategies for enhancing your manufacturing operations. This meeting marks the beginning of our partnership towards achieving manufacturing excellence.

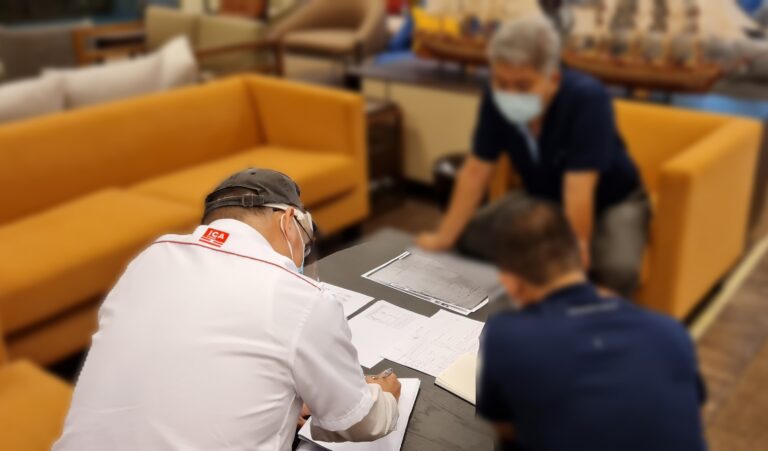

Step 2: On-site feasibility study with customers

Our on-site feasibility studies are integral to this process, involving immersive visits to analyze and assess clients’ readiness for technological advancement. Through close collaboration and meticulous evaluation of people, processes, technology, and finances, we identify areas ripe for enhancement. These studies serve as the foundation for crafting tailored strategies aimed at streamlining operations, improving efficiency, and driving sustainable growth.

Step 3: Generic Readiness Assessments (GRA)

Our company conducts General Readiness Assessments (GRAs) of manufacturing facilities based on the SIRIM criteria for Industry 4.0 maturity. We assess the technical infrastructure, data management, workforce capabilities and processes. The level of assessment gives us a comprehensive view of a facility’s readiness to adopt Industry 4.0. Our assessment identifies strengths and areas of improvement and provides tailored solutions and recommendations. Ultimately, we help manufacturing organizations embrace the principles of Industry 4.0 to improve efficiency, innovation and competitiveness.

Step 4: Proposal

Our company proposes and establishes a tailored solution based on the facility’s assessment level. We analyze GRA results, engage stakeholders, and develop a customized plan aligned with the company’s goals. This includes defining KPIs, creating a detailed roadmap, and ensuring ongoing support. Our approach fosters collaboration, transparency, and a clear path toward successful manufacturing transformation.

Step 5: Implementation

In the implementation phase, our company executes the proposed solution tailored to the manufacturing facility’s needs. We coordinate resources, deploy technologies, and provide employee training and mentoring for seamless adoption. Throughout the process, we closely monitor performance against established KPIs, make adjustments as needed, and maintain open communication with stakeholders. This ensures alignment with the factory transformation goal and fosters continuous improvement in manufacturing processes.